Busbar Busduct Machines- A New Era for Electrical Housing

In the realm of electrical engineering, the innovation of busbar busduct machines has heralded a new era in electrical housing. These machines have revolutionized the way electrical power distribution systems are constructed and installed, offering unprecedented efficiency, safety, and flexibility. This article aims to explore the various aspects of busbar busduct machines and their impact on the electrical housing industry.

The Evolution of Electrical Housing

Over the years, the demand for electricity has grown exponentially, necessitating the development of more advanced and efficient methods for power distribution. Traditional cable-based systems, while effective, have limitations in terms of installation time, space requirements, and maintenance. This led to the evolution of busbar busduct systems, which have redefined the way electrical power is distributed within buildings and industrial complexes.

Advantages of Busbar Busduct Machines

The introduction of busbar busduct machines has brought about several key advantages that have significantly improved the efficiency and safety of electrical housing installations. These advantages include:

1. Enhanced Flexibility: Busbar busduct systems offer greater flexibility in terms of design and installation, allowing for customized solutions to meet specific project requirements. The machines used to fabricate busbars and busducts are capable of producing complex shapes and configurations, enabling engineers to tailor the system to the unique needs of each project.

2. Efficient Installation: The use of busbar busduct machines streamlines the installation process, significantly reducing the time and labor required to set up electrical distribution systems. This not only results in cost savings but also minimizes disruptions to ongoing operations during installation.

3. Improved Safety: Busbar busduct systems are designed to meet rigorous safety standards, reducing the risk of electrical faults and ensuring a reliable and secure power distribution network. The precision manufacturing capabilities of busbar busduct machines contribute to the overall safety and reliability of the system.

4. Space Optimization: Compared to traditional cable-based systems, busbar busduct solutions require significantly less space, making them ideal for installations where space is at a premium. This compact design also allows for easier integration with other building services, maximizing the busbar machine efficient use of available space.

The Role of Busbar Busduct Machines in Electrical Housing

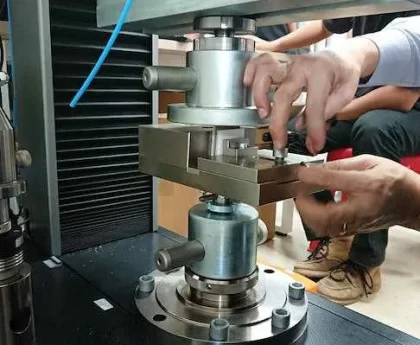

As the demand for more advanced and efficient electrical housing solutions continues to grow, busbar busduct machines play a crucial role in meeting these demands. These machines are instrumental in fabricating the intricate components that make up busbar busduct systems, allowing for precise and consistent production of components such as busbars, elbows, tees, and supports.

By utilizing advanced manufacturing techniques such as CNC punching, bending, and shearing, busbar busduct machines ensure the high quality and accuracy of each component, resulting in a reliable and durable electrical housing solution. Additionally, the ability of these machines to work with a variety of materials, including copper and aluminum, further enhances the versatility and adaptability of busbar busduct systems.

Applications and Industries

The versatility of busbar busduct machines has led to their widespread adoption across various industries and applications. From commercial and residential buildings to industrial facilities and data centers, busbar busduct systems have become the go-to solution for efficient and reliable power distribution. The ability to customize the system to suit specific project requirements makes busbar busduct machines suitable for a wide range of applications, including:

1. High-rise Buildings: The space-saving design of busbar busduct systems makes them particularly well-suited for high-rise buildings, where efficient use of space is essential. The flexibility of the system allows for seamless integration with the building’s architecture and other services.

2. Industrial Facilities: In industrial settings, where power distribution requirements can be complex and demanding, busbar busduct systems offer a robust and adaptable solution. The ability to handle high current ratings and the ease of maintenance make these systems ideal for industrial applications.

3. Data Centers: Data centers require highly reliable and scalable power distribution solutions to support the critical operations of IT equipment. Busbar busduct systems provide the necessary flexibility and scalability to meet the evolving needs of data centers, ensuring uninterrupted power supply.

Challenges and Opportunities

While busbar busduct machines have brought about significant advancements in electrical housing, they also present certain challenges and opportunities for the industry. One of the primary challenges is the need for skilled personnel to operate and maintain these sophisticated machines. As such, there is a growing demand for training programs to equip professionals with the necessary skills to leverage the capabilities of busbar busduct machines effectively.

On the other hand, the rapid advancements in technology and manufacturing processes present opportunities for further innovation in busbar busduct machines. Integrating smart technologies, automation, and digitalization into these machines can enhance their performance, efficiency, and predictive maintenance capabilities, further elevating the standard of electrical housing solutions.

Future Trends

Looking ahead, the future of busbar busduct machines in electrical housing is poised for continued innovation and evolution. The integration of advanced materials, such as composite conductors and insulation, can further enhance the performance and efficiency of busbar busduct systems. Additionally, the adoption of digital twin technology and real-time monitoring capabilities will enable proactive maintenance and optimization of electrical housing installations.

Furthermore, the convergence of busbar busduct systems with renewable energy sources and energy storage solutions presents exciting possibilities for sustainable and resilient power distribution networks. By seamlessly integrating these technologies, busbar busduct machines can facilitate the transition towards greener and more efficient electrical housing solutions.

Conclusion

The advent of busbar busduct machines has undoubtedly ushered in a new era for electrical housing, offering unparalleled flexibility, efficiency, and safety. As the demand for more advanced power distribution solutions continues to grow, the role of these machines in shaping the future of electrical engineering cannot be overstated. With ongoing advancements and innovations, busbar busduct systems are poised to redefine the standards of electrical housing, paving the way for a more reliable, sustainable, and efficient power distribution infrastructure.

https://iflatiron.com/