Laser engraving machines are becoming increasingly popular among hobbyists, artists, and small business owners alike due to their ability to quickly and accurately etch designs onto a wide variety of materials. In this article, we will explore some general knowledge about laser engraving machines, including their history, how they work, and the different types available on the market.

History of laser engraver for wood Laser Engraving Machines

The first laser was invented in 1960 by Theodore Maiman, and it didn’t take long for researchers to begin exploring the potential applications of this revolutionary technology. One of the earliest uses developed for lasers was in the field of engraving, and the first commercial laser engraving machine was introduced in 1971 by Western Electric.

Initially, laser engraving was primarily used in industrial settings to etch serial numbers or other identifying marks onto metal parts and components. However, advances in technology have made laser engraving more accessible and affordable, allowing small businesses and individuals to take advantage of this powerful tool.

How Laser Engraving Works

At its core, laser engraving is a process that uses a high-powered laser beam to burn away material from a surface, leaving behind an engraved or etched design. The laser beam is typically controlled by a computer program that directs it along a pre-determined path to create the desired design.

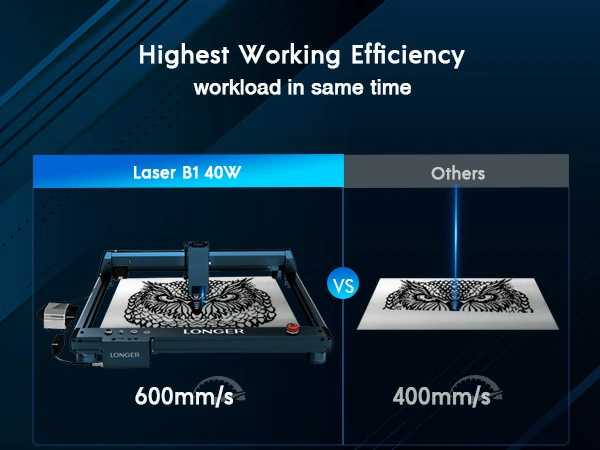

The intensity of the laser beam can be adjusted to vary the depth and width of the engraving, and different types of lasers can be used to etch a wide range of materials, from wood and plastics to metals and glass. The precision and speed of laser engraving make it a popular choice for creating highly detailed designs or reproducing complex patterns with ease.

Types of Laser Engraving Machines

There are several different types of laser engraving machines available on the market, each with its own strengths and weaknesses. Some of the most common types include:

1. CO2 Laser Engraving Machines

CO2 lasers are the most commonly used type of laser in engraving machines due to their versatility and affordability. They work by using a gas-filled tube to create a high-powered laser beam that can be focused onto a surface to create an engraving. CO2 lasers can be used on a wide range of materials, including wood, acrylic, leather, and some metals.

2. Fiber Laser Engraving Machines

Fiber lasers are more expensive than CO2 lasers but are often preferred for their precision and speed. They use a solid-state laser to generate a high-powered beam that is highly focused and capable of etching even the tiniest details onto metal surfaces.

3. Diode Laser Engraving Machines

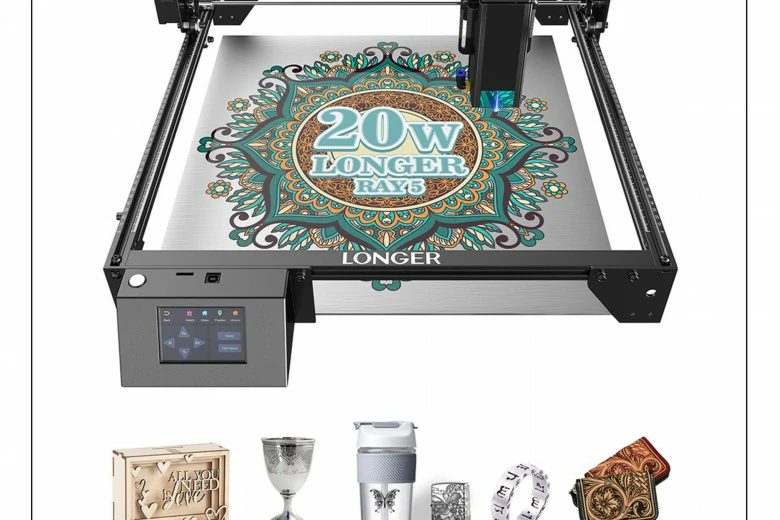

Diode lasers are typically used for smaller-scale engraving projects due to their lower power output. They are commonly used for marking or etching designs onto plastics, fabrics, and other softer materials.

Laser engraving machines have revolutionized the way we design, create, and produce products. Whether you’re a hobbyist looking to create custom pieces for your home or a small business owner looking to add value to your products, laser engraving technology can help you achieve your goals with ease. Understanding the basics of how these machines work and the different types available can help you make an informed decision when choosing the right laser engraving machine for your needs.