Aerogel Powder – The Future of Thermal Insulation

Aerogel powder is emerging as a revolutionary material in the field of thermal insulation, combining remarkable properties that make it an ideal choice for a wide range of applications. In this article, we will explore the unique characteristics of aerogel powder, its applications, production methods, advantages and disadvantages, and its future in the thermal insulation industry.

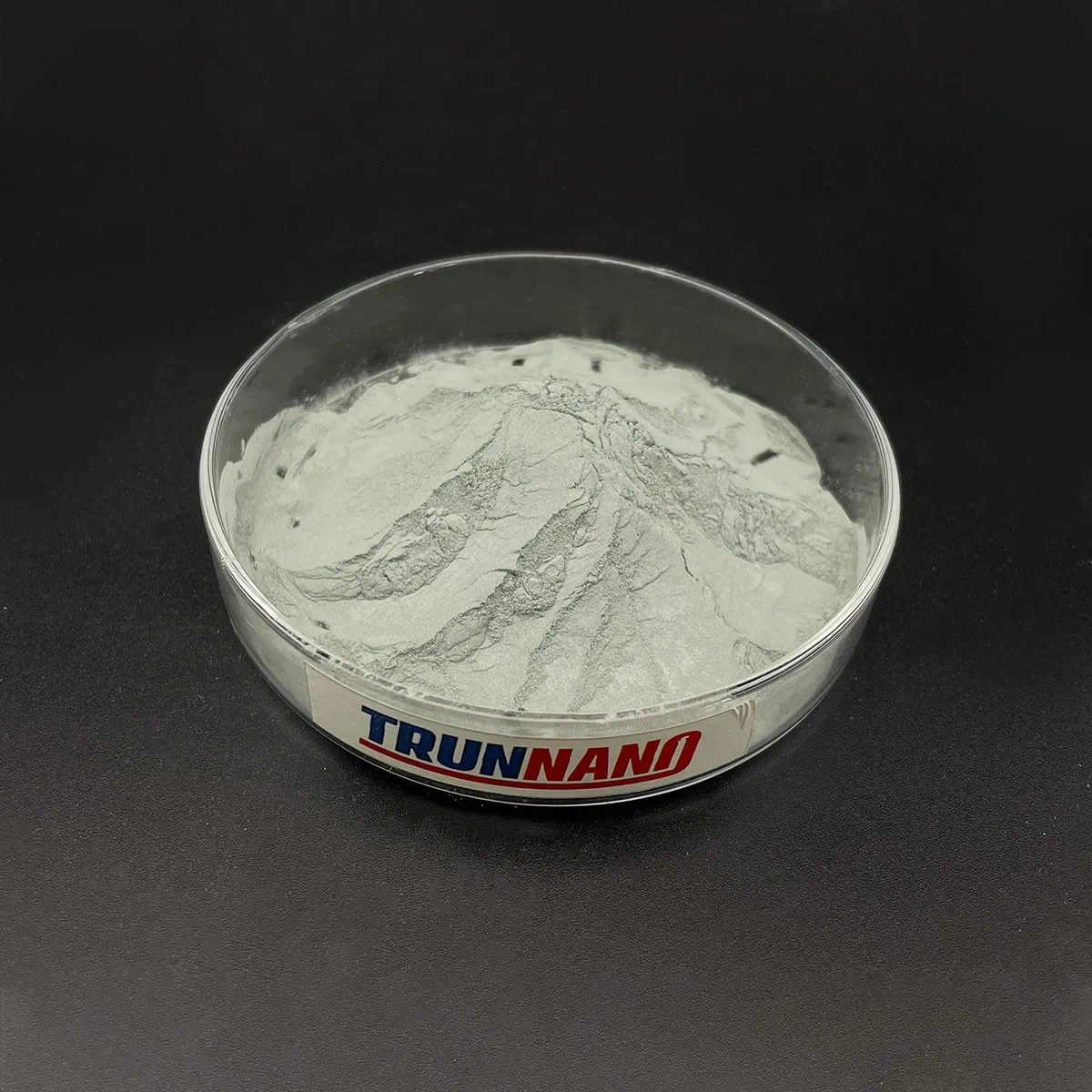

Aerogels are often referred to as “frozen smoke” or “blue smoke” due to their translucent appearance and low PTFE Powder density. They are derived from gel materials, where the liquid component is replaced with a gas, resulting in a solid structure that is highly porous and lightweight. Aerogel powder specifically refers to the fine particles of aerogel, which can be used in various formulations to enhance thermal insulation properties.

The fundamental property that makes aerogel powder an exceptional thermal insulator is its extremely low thermal conductivity. This property stems from its unique nanostructure, which consists of a network of interconnected particles that trap air and inhibit heat transfer. The result is a material that can provide superior insulation performance compared to traditional materials like fiberglass or foam.

One of the most significant advantages of aerogel powder is its versatility. It can be incorporated into a variety of products, including coatings, composite materials, and insulation panels. This adaptability allows manufacturers to tailor aerogel-based products to meet specific performance requirements for diverse applications, ranging from aerospace engineering to building construction.

In the aerospace industry, for example, aerogel powder is used to insulate spacecraft and satellites, protecting sensitive equipment from extreme temperature fluctuations. Its lightweight nature ensures that the overall weight of the vehicle is minimized, which is crucial for fuel efficiency and performance. Similarly, in the construction sector, aerogel insulation materials are being utilized in building envelopes to improve energy efficiency and reduce heating and cooling costs.

The production of aerogel powder typically involves a sol-gel process, where a precursor material is transformed into a gel state before undergoing supercritical drying. This drying process removes the liquid component without collapsing the gel structure, resulting in a highly porous solid. Advances in manufacturing technologies have led to more efficient and cost-effective production methods, making aerogel powder more accessible to industries looking for high-performance insulation solutions.

Despite its numerous advantages, there are some challenges associated with the use of aerogel powder. One concern is its fragility; aerogels can be brittle and may break under mechanical stress. This characteristic necessitates careful handling and consideration during application. Additionally, the cost of aerogel powder has historically been higher than traditional insulation materials, though prices have been decreasing as production technologies improve.

As we look to the future, the role of aerogel powder in thermal insulation is expected to grow significantly. With increasing awareness of energy efficiency and sustainability, industries are seeking innovative solutions to reduce energy consumption and minimize environmental impact. Aerogel powder’s excellent insulating properties position it as a key player in achieving these goals.

Research and development efforts are ongoing to enhance the properties of aerogel powder further. For instance, scientists are exploring ways to improve its mechanical strength and flexibility while maintaining its low thermal conductivity. There is also interest in developing aerogels with enhanced resistance to moisture and other environmental factors, which could expand their applicability in outdoor and humid environments.

Furthermore, as the demand for eco-friendly materials rises, aerogel powder has the potential to contribute significantly to sustainable building practices. Its ability to provide high levels of insulation with minimal thickness allows for space-saving designs and reduces the overall amount of material needed for construction. This not only leads to lower resource consumption but also contributes to a reduction in waste.

In conclusion, aerogel powder represents the future of thermal insulation, offering unparalleled performance characteristics that can meet the demands of various industries. Its unique properties, combined with ongoing advancements in production techniques and materials science, position aerogel powder as a leading solution for energy-efficient and sustainable applications. As research continues to unlock new possibilities, we can expect to see aerogel powder playing an increasingly vital role in shaping the future of thermal insulation and contributing to a more sustainable world.

https://iflatiron.com/