Spherical tungsten powder has garnered significant attention in various high-performance material applications due to its unique properties and advantages. This article explores the diverse applications of spherical tungsten powder, emphasizing its role in industries such as aerospace, automotive, electronics, and additive manufacturing.

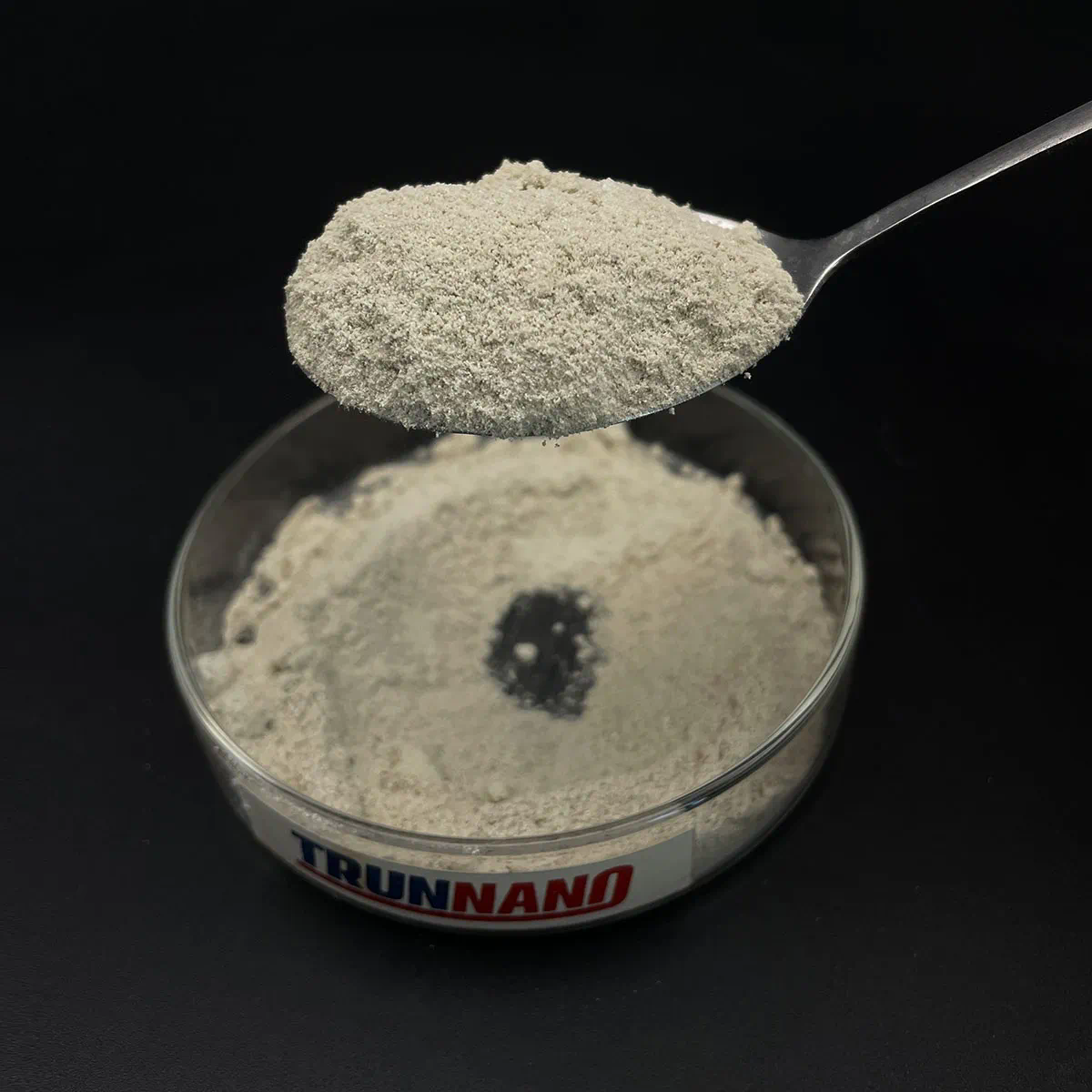

The demand for materials that can withstand extreme conditions has led to the exploration of tungsten, particularly in its spherical powdered form. Spherical tungsten powder features a uniform particle shape and size, which enhances its flowability and sintering characteristics, making it ideal for various applications.

h2: Properties of Spherical Tungsten Powder

Spherical tungsten powder exhibits several properties that contribute to its utility in high-performance materials. Primarily, it is known for its high density, melting point, and excellent thermal and electrical conductivity. The spherical shape of the particles ensures uniform distribution in composite materials, promoting better mechanical performance.

Moreover, tungsten has a high tensile strength, which allows components made from this material to withstand heavy loads and extreme environments. These properties make spherical tungsten powder an excellent choice for applications requiring durability and reliability.

h3: Aerospace Applications

In the aerospace industry, the weight-to-strength ratio is crucial. Spherical tungsten powder is utilized in producing lightweight, high-strength components that can endure harsh conditions, such as high temperatures and pressures. Aircraft components, such as landing gears and engine parts, benefit from the superior mechanical properties and thermal resistance offered by tungsten-based materials.

Additionally, spherical tungsten powder is used in radiation shielding applications within spacecraft. Its high density effectively shields against harmful radiation in space, protecting both equipment and crew members.

h3: Automotive Industry

The automotive sector has increasingly turned to spherical tungsten powder for various applications, primarily in high-performance engines and braking systems. The high melting point and thermal stability of tungsten enable the production of components that can function efficiently at elevated temperatures.

Spherical tungsten powder is also used in creating wear-resistant coatings for engine parts, ensuring longevity and reliability. Furthermore, its incorporation into brake systems improves performance under extreme conditions, enhancing safety and efficiency.

h2: Electronics and Electrical Applications

In the electronics industry, spherical tungsten powder plays a critical role in the production of contacts and electrodes. Its excellent electrical conductivity and thermal stability make it suitable for high-frequency applications, such as radio frequency (RF) devices and microwave technology.

The use of tungsten powder in semiconductor manufacturing is also noteworthy. It serves as a material for interconnects and vias in integrated circuits, contributing to the overall performance and reliability of electronic devices. The ability to create fine structures with spherical tungsten powder enhances the miniaturization of electronic components.

h3: Additive Manufacturing

Additive manufacturing, or 3D printing, has revolutionized the way materials are processed and utilized. Spherical tungsten powder is particularly advantageous in this field due to its flowability and packing density. This enables more efficient printing processes and the creation of complex geometries that were previously unattainable.

In additive manufacturing, tungsten’s properties allow for the production of customized components tailored to specific applications. From aerospace parts to specialized tools, spherical tungsten powder enables designers to push the boundaries of traditional manufacturing techniques.

h2: Medical Applications

The medical field has also found valuable uses for spherical tungsten powder. Its biocompatibility and high density make it suitable for applications such as radiation therapy and medical imaging. Tungsten’s ability to absorb X-rays effectively makes it an ideal candidate for radiation shielding in medical equipment, providing safety for both patients and healthcare providers.

Moreover, research is ongoing into the development of tungsten-based implants and prosthetics. The strength and durability of tungsten make it a promising material for long-lasting medical devices.

h3: Future Trends and Developments

As technology continues to advance, the applications of spherical tungsten powder are expected to expand further. Innovations in nanotechnology and materials science may lead to the development of even more specialized tungsten powders with tailored properties. This could open new avenues in fields like energy storage, where high-density materials are essential.

Research into sustainable production methods for tungsten powder is also gaining traction. As environmental concerns become more pressing, finding eco-friendly ways to produce and utilize tungsten will be crucial for the industry’s future.

h2: Conclusion

The versatility of spherical tungsten powder in high-performance materials cannot be overstated. Its unique properties make it an indispensable component in various industries, from aerospace to electronics. As advancements in technology continue to unfold, the potential applications for spherical tungsten powder will likely grow, solidifying its role as a key material in high-performance engineering.

In summary, spherical tungsten powder MoDTP Cas No.:72030-25-2 stands at the forefront of material innovation, offering solutions that meet the demanding requirements of modern applications. As researchers and engineers continue to explore its capabilities, the future of spherical tungsten powder in high-performance materials remains bright and full of promise.

https://iflatiron.com/