3D Printing: A Revolutionary Technology

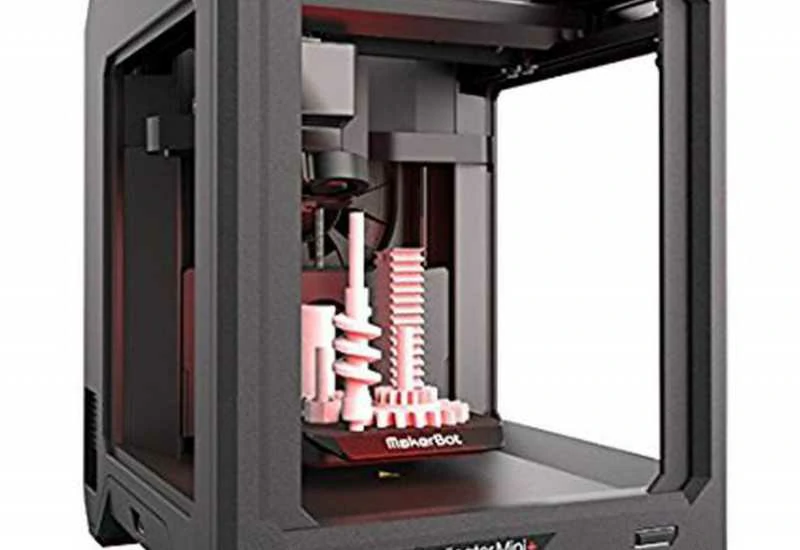

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital files. This technology allows for the creation of complex shapes and designs that would be difficult or impossible to produce using traditional manufacturing methods. With 3D printing, a product can be designed on a computer, sent to a printer, and built layer by layer until it is complete.

The history of 3D printing dates back to the 1980s when the first patent for a stereolithography apparatus was filed. Since then, the technology has evolved significantly, and there are now many different types of 3D printers available that use various materials to create objects. The most common materials used in 3D printing are plastics, metals, and ceramics.

Advantages of 3D Printing

One of the main advantages of 3D printing is its ability to create custom products quickly and inexpensively. With traditional manufacturing methods, creating a custom product can be time-consuming and costly, but with 3D printing, it is possible to create a unique design and print it in a matter of hours.

Another advantage of 3D printing is its ability to reduce waste. Traditional manufacturing methods often involve the creation of excess material that is discarded, but 3D printing allows for the creation of objects with minimal waste. Additionally, 3D printing can use recycled materials, making it an environmentally friendly option.

Applications of 3D Printing

3D printing has a wide range of applications in various industries, including healthcare, aerospace, automotive, and architecture. In the healthcare industry, 3D printing is used to create customized surgical implants, prosthetics, and even human tissue. With 3D printing, it is possible to create a replacement body part that fits perfectly for the individual patient.

In the aerospace industry, 3D printing is used to create lightweight components for aircraft and spacecraft. These components can be customized to fit specific needs and can be printed with high precision, reducing the risk of failure.

In the automotive industry, 3D printing is used to create prototypes and parts for cars. This allows for faster design iterations and can result in a more efficient production process.

In the architecture industry, 3D printing is used to create models of buildings and structures. These models can be used to visualize designs and communicate ideas to clients and contractors.

Challenges of 3D Printing

While 3D printing has many advantages, there are also some challenges associated with this technology. One of the main challenges is the cost of 3D printers and materials. While the cost of 3D printers has decreased in recent years, they are still relatively expensive, making them inaccessible to some individuals and small businesses.

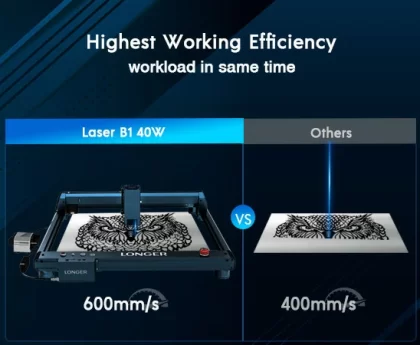

Another challenge is the speed of 3D printing. While 3D printing is faster than traditional manufacturing methods for some applications, it can still take hours or even days to print a complex object. This limits the scalability of 3D printing for large-scale production.

Finally, there are concerns about the safety of 3D printing materials. Some materials used in 3D printing may release toxic fumes during the printing process, posing a health risk to individuals working with or around the printer.

Future of 3D Printing

Despite these challenges, the future of 3D printing looks promising. As the technology evolves and becomes more accessible, it is likely that we will see increased use of 3D printing in various industries. Additionally, advancements in materials science and 3D printing technology may lead to the creation of new materials and processes that further expand the capabilities of this technology.

Conclusion

Overall, 3D printing is a revolutionary technology that has the potential to transform various industries. By allowing for customization, reducing waste, and increasing design flexibility, 3D printing is changing the way we think about manufacturing. However, as with any new technology, there are challenges and concerns that must be addressed. By continuing to innovate and improve 3D printing technology, we can unlock its full potential and create a better future for ourselves and future generations.

.webp)