1. Understand the Basics of Mold Polishing

Mold polishing is an essential process in the manufacturing industry, particularly in the production of injection molds. It involves the removal of imperfections and inconsistencies on the surface of a mold to achieve a smooth and flawless finish. Understanding the basics of mold polishing techniques is crucial for achieving optimal results. Here are six tips to help you master the art of mold polishing.

2. Start with Proper Surface Preparation

Before you begin the actual polishing process, it’s important to prepare the surface of the mold properly. This involves cleaning the mold thoroughly to remove any dirt, grease, or residue. Use a solvent or a mild detergent solution to clean the mold, and make sure to dry it completely before moving on to the next step. Proper surface preparation ensures that the polishing process is more effective and enhances the overall quality of the finished product.

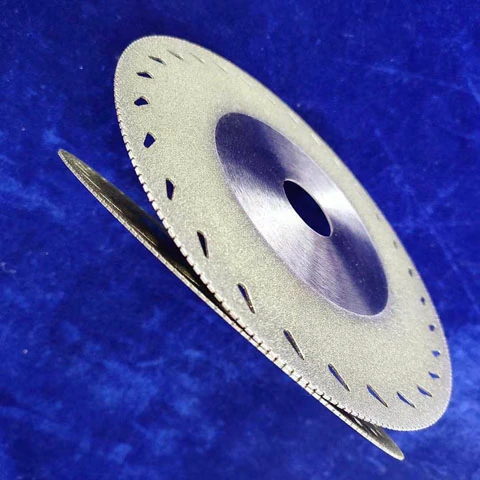

3. Choose the Right Tools and Abrasives

When it comes to mold polishing, using the right tools and abrasives is crucial. There are various types of tools and abrasives available in the market, such as stones, diamond compounds, and polishing pastes. The choice of tools and abrasives depends on the type of mold material and the desired level of polish. For example, softer materials may require finer abrasives, while harder materials may require coarser abrasives. Experiment with different tools and abrasives to find the best combination for your specific needs.

4. Follow Proper Polishing Techniques

Polishing is not just about random rubbing and buffing. It requires following proper techniques to achieve a consistent and high-quality finish. One important technique is to use consistent pressure and movement when polishing the mold. Applying too much pressure can lead to uneven surfaces, while applying too little pressure can result in an ineffective polish. Another technique is to use a circular or figure-eight motion when polishing, as this helps distribute the abrasives evenly and prevents the formation of swirl marks.

5. Use the Right Polishing Compounds

Polishing compounds are used to enhance the polishing process and achieve a mirror-like finish on the mold surface. There are different types of polishing compounds available, such as cutting compounds, polishing compounds, and finishing compounds. Cutting compounds are used for initial rough polishing, polishing compounds for intermediate polishing, and finishing compounds for final polishing. Choose the right polishing compound based on the level of polish required and the type of material being polished.

6. Perform Regular Inspections

Lastly, it’s important to perform regular inspections during the mold polishing process. Inspect the mold surface at regular intervals to ensure that all imperfections are being removed effectively and that the desired level of polish is being achieved. If any defects or inconsistencies are found, go back to the previous step and make the necessary adjustments. Regular inspections help maintain quality control and ensure that the final product meets the desired specifications.

In conclusion, mastering the art of mold polishing requires understanding the basics, proper surface preparation, choosing the right tools and abrasives, following proper polishing techniques, using the right polishing compounds, and performing regular inspections. By following these six tips, you can achieve a smooth and flawless finish on your molds, resulting in high-quality products in the manufacturing industry.

.webp)